Porsche trials private 5G network

The high-performance car manufacturer heads into new remote production era with Ericsson SA network.

Get up to speed with 5G, and discover the latest deals, news, and insight!

You are now subscribed

Your newsletter sign-up was successful

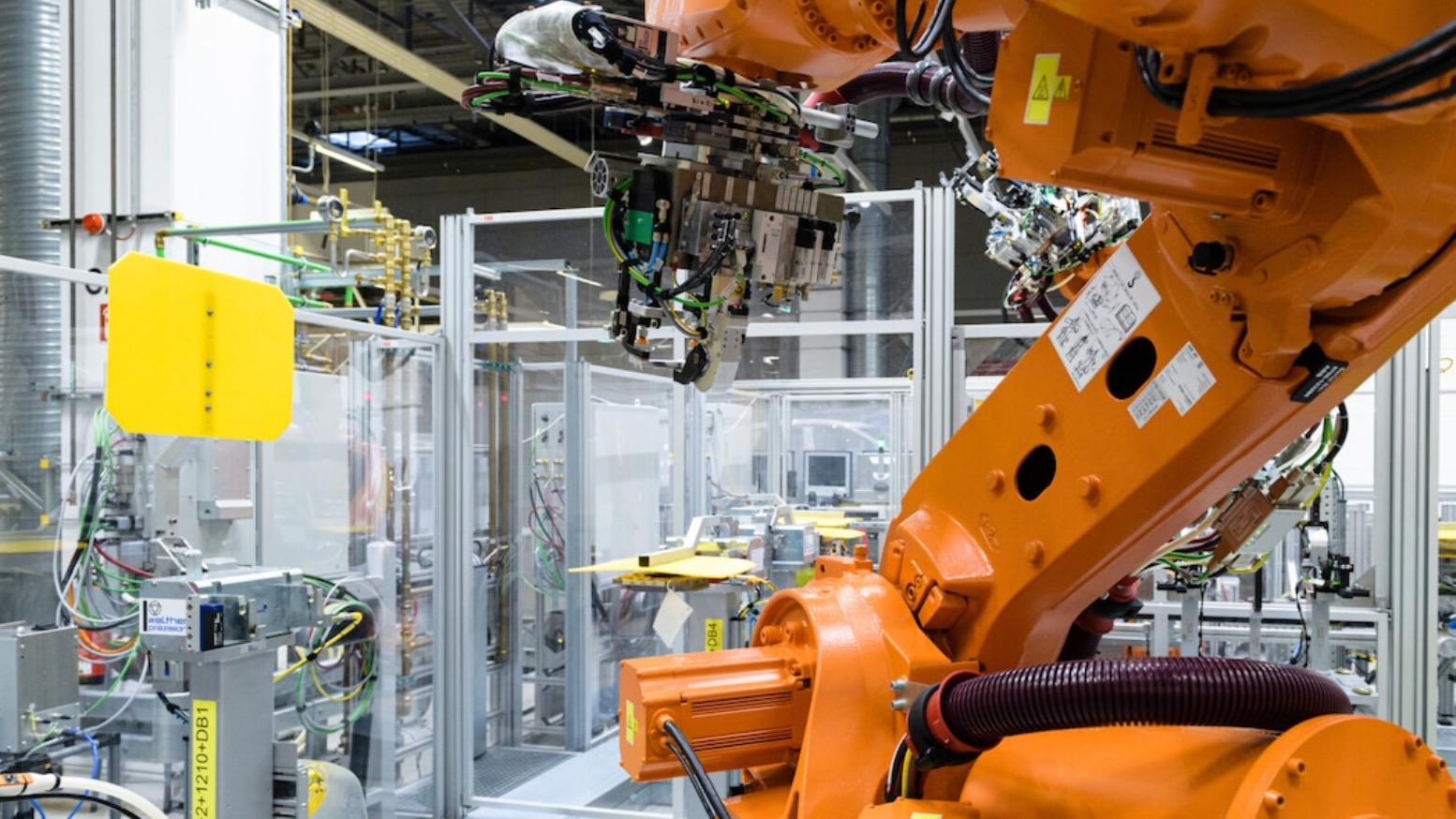

A research partnership between Ericsson and Porsche is leveraging the power of 5G to accelerate production capabilities at Porsche’s manufacturing production complex in Leipzig, Germany. The trial project is the first deployment of a private 5G network at any of Porsche’s production complexes, indicating a new remote production era for the high-performance car manufacturer.

“5G technology is one of the key elements laying the groundwork for our Smart Factory.”

Albrecht Reimold, Porsche AG.

“As we transition to the factory of tomorrow, Porsche production is undergoing a comprehensive digital transformation. In the process, we are guided by our vision: smart, lean and green. 5G technology is one of the key elements laying the groundwork for our Smart Factory”, says Albrecht Reimold, Member of the Executive Board for Production and Logistics at Porsche AG.

Dedicated 5G network

Ericsson’s secure standalone network operates over a private frequency spectrum, providing high-speed wireless connectivity, ultra-low latency and huge data-handling capabilities. Porsche’s dedicated 5G network will be piloted in the technology cell of Porsche’s Macan body shop and will enable the control of robotics in real time without cables. It also allows for the transmission of massive amounts of data between other on-site machines, production workers and vehicles through the secure, flexible and predictable transmission of signals in real time.

“Important step forward in our production of the future.”

Gerd Rupp, Porsche Leipzig.

“The 5G test area offers an excellent opportunity to test use cases in a production context and is an important step forward in our production of the future,” said Gerd Rupp, Chairman of the Executive Board, Porsche Leipzig.

Automation capabilities

The updated automation capabilities will have a significant impact on production at Porsche, providing numerous benefits for the company and its workers, including increased worker safety and a more efficient form of quality: faster production times, reduced costs and increased quality.

“Ericsson is proud to work with leading companies like Porsche in their smart factories and provide them with our world leading 5G and Private Network products. 5G connectivity can enable the next step in digital transformation in manufacturing, making it more efficient and effective. Ericsson’s Private Networks empower greater productivity, safety and flexibility across a variety of industries from manufacturing, processing, mining, offshore, and beyond,” said Åsa Tamsons, Head of Business Area Technologies and New Businesses at Ericsson.

Get up to speed with 5G, and discover the latest deals, news, and insight!

- Why 5G small cells are vital for mmWave 5G

- Get updates on the hottest 5G stocks

- Discover the truth behind 5G dangers

- 5G towers: everything you need to know

Rachael is a British journalist with 17 years experience in the publishing industry. Since launching www.digitalcameraworld.com, she’s been freelancing, and working for some of the world’s best-loved websites and magazines including T3.com and TechRadar.com and has also had a book, iPad for Photographers, published. A regular contributor at 5Gradar, Rachael is following the 5G market closely. Find out more at www.rachaelsharpe.com