Volkswagen launches pilot local 5G network for its production operations

5G being tested by Volkswagen for production on its way to smart factories

Get up to speed with 5G, and discover the latest deals, news, and insight!

You are now subscribed

Your newsletter sign-up was successful

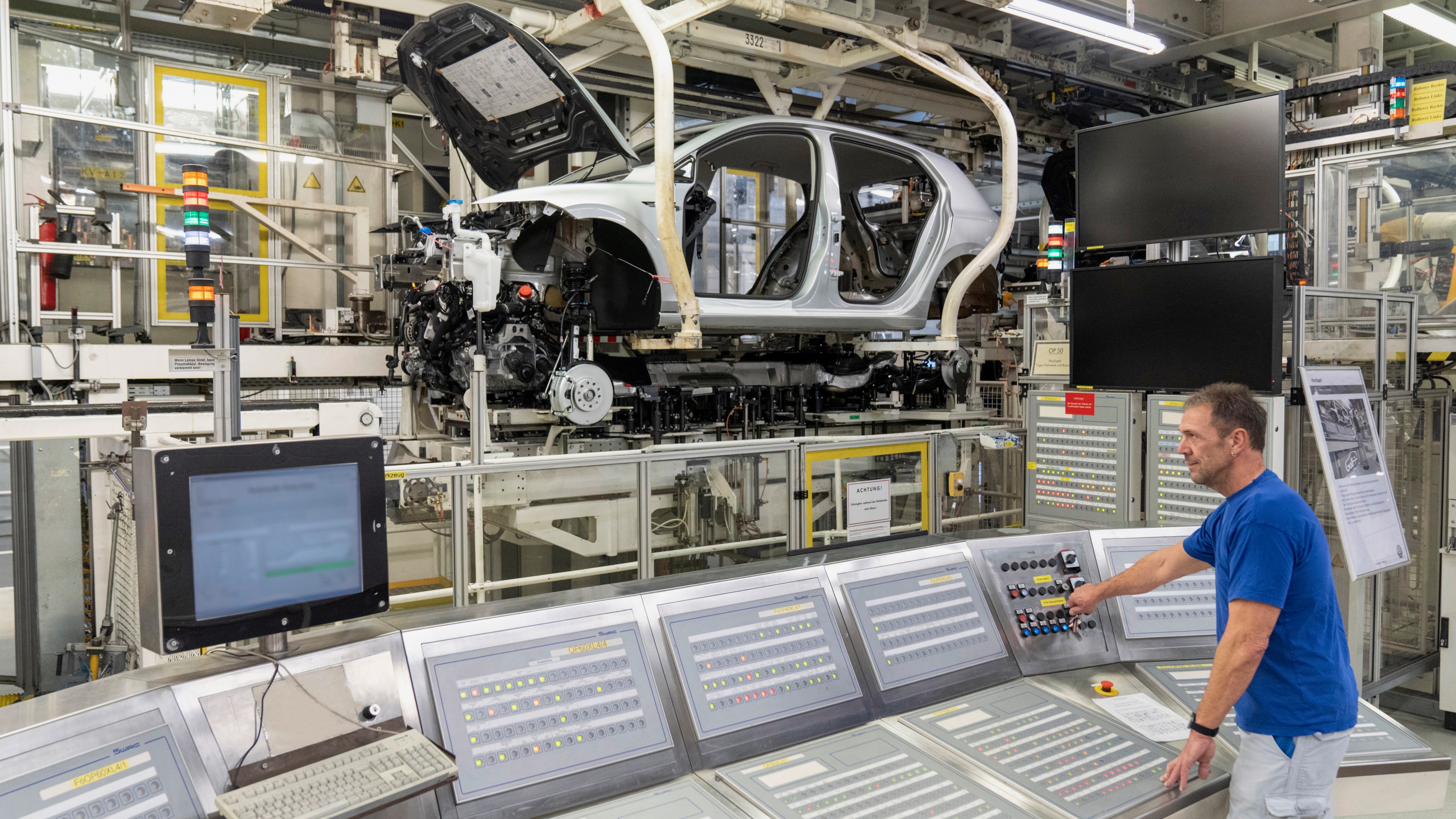

Volkswagen has announced it is taking a further step in the direction of fully networked factories. A local 5G standalone network, dubbed “campus network” is now available at its main plant in Wolfsburg, which is initially covering the main production development centre and the pilot hall.

The pilot project will test whether the 5G technology meets the demanding requirements of vehicle production with a view to developing this for industrial series production in the future. A dedicated 5G radio frequency will be used to safeguard secure, delay-free transmission of data. The Transparent Factory in Dresden has also put a so-called “5G island” into operation. Volkswagen undertakes setup and operation of the 5G infrastructure itself in a move designed to build up competitive expertise in using this important technology of the future and ensure data security.

“5G technology has great potential for innovation.”

Christian Vollmer, Volkswagen.

“In implementing our accelerate strategy we are working at full speed to transform our Volkswagen sites into smart factories. Our goal is to continuously optimise our production and make it even more efficient and flexible. We believe that 5G technology has great potential for innovation, from the use of intelligent robots and driverless transportation systems to networked control of plant and machinery in real time up to wireless software flashing of manufactured vehicles,” said Christian Vollmer, Member of the Board of Management of the Volkswagen Brand responsible for Production and Logistics.

Real-time data transfer

One scenario to be tested in the pilot phase under real-life laboratory conditions in Wolfsburg is the wireless upload of data to manufactured vehicles. With ever higher levels of digitisation and fully connected vehicles, the production process requires large amounts of data to be transmitted to the cars. 5G makes it possible to perform this much more quickly and at any time during production. Indeed, as there are already around 5,000 robots at the Volkswagen plant in Wolfsburg, as well as many other machines and systems, secure, delay-free transmission of data will be required in the future to control and monitor these.

“5G has the potential to be one such driver of the Industrial Internet of Things.”

Beate Hofer, Volkswagen Group.

“Efficient wireless communication in real time will be crucial for flexible production in the future. 5G has the potential to be one such driver of the Industrial Internet of Things. Our aim is therefore to build up extensive experience in the operation and industrial use of 5G technology,” said Beate Hofer, CIO of the Volkswagen Group.

“Interference-free, high-availability wireless transmission requires a dedicated frequency.”

Volkswagen

Volkswagen is using Nokia network equipment for the 5G pilot network but setting up and operating the local 5G infrastructure itself - for the campus network in Wolfsburg, the company applied for and was allocated a private radio frequency at 3.7 to 3.8 GHz with 100 MHz bandwidth by the Federal Network Agency. Exclusive spectrum is a key enabler for 5G campus operations at the manufacturing site. “Interference-free, high-availability wireless transmission requires a dedicated frequency that will be used exclusively by Volkswagen for production purposes,” said Volkswagen, in a press statement.

Get up to speed with 5G, and discover the latest deals, news, and insight!

- Why 5G small cells are vital for mmWave 5G

- Get updates on the hottest 5G stocks

- Discover the truth behind 5G dangers

- 5G towers: everything you need to know

Rachael is a British journalist with 17 years experience in the publishing industry. Since launching www.digitalcameraworld.com, she’s been freelancing, and working for some of the world’s best-loved websites and magazines including T3.com and TechRadar.com and has also had a book, iPad for Photographers, published. A regular contributor at 5Gradar, Rachael is following the 5G market closely. Find out more at www.rachaelsharpe.com